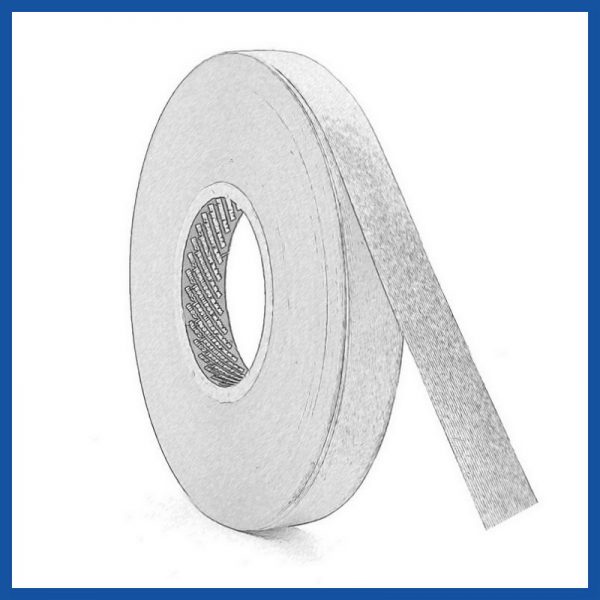

Description

A soft feel thermoplastic polyurethane two-layer seam tape with high melting hot melt. Suitable for all coated and laminated and stretchy fabrics. It is widely used by manufacturers of fashionable rainwear, skiwear, and other work wear apparel to waterproof sewn seams. Suitable for light to medium weight fabrics used by high branded sports wear produces.

Product technical data (T2U4GY)

| Mfc code | T2UGY seam tape |

| TechDescription |

|

| Composition |

|

| Packing |

|

| Machine settings |

|

| Comments |

|