MACHINE SETTINGS

MACHINE SETTINGS

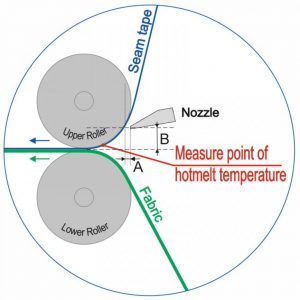

Distance between nozzle and sealing tape – A [mm]

Distance between nozzle and sealing tape – B [mm]

Nozzle Temperature [Deg C]

Nozzle Air Flow [kgf/cm2]

Upper Heated Roller (if Applicable) [Deg C]

Upper Roller Pressure [kgf/cm2]

Machine roller speed [m/min]

Nozzle Size 22mm for 20mm tapes

Nozzle Size 26mm for 20-22mm tapes

Nozzle Position A

- Position A will affect the actual temperature of the hot melt. Basically as the distance of A is reduced the temperature of the hot melt layer of the seam tape will rise and will become more viscous and will be more advantageous to adhesion to the garment fabric.

- For 1 layer and 2 layer tapes we recommend a basic starting position of 2mm as the tape may burn and may touch the nozzle in addition the tapes are less viscous.

- For 3 layer tapes we recommend a basic starting position of 1mm due to the need to achieve a high viscosity of the hot melt to secure a waterproof seam and allow full penetration of the knit of the garment fabric.

Nozzle Position B

- Position B will affect fabric damage by scorching by hot air from the nozzle. If the distance of B is set at the correct height fabric damage will be eliminated and will give a very esthetical and advantageous finish after sealing.

- Changing position B will also affect the actual temperature of the hot melt due to the nozzle air angle in relation to the tape. As this distance of B is increased the nozzle air becomes closer to a right angle and thus increases the temperature of the hot melt.

- For 1 layer and 2 layer tapes we recommend a basic starting position of 5mm with a shorter distance you will also pre-heat the fabric and increase the bonding and adhering strength of the tape.

- For 3 layer tapes we recommend a basic starting position of 10mm to help prevent the lining fabric being damaged from the heat of the air from the nozzle.

Nozzle Air Temperature

- This will largely affect the activation of the hot melt layer of the tape.

- It is the easiest and most common factor in adjusting the adhering properties of the seam tape.

- The hot melt temperature also known as the adhering temperature is = to the sum of the nozzle temperature and the Nozzle air flow.

- For 1-layer and 2 layer tapes we recommend a basic starting position of 400 Deg C. although this starting temperature can be increased or decreased along with the air nozzle air flow.

- For 3 layer tapes we recommend a basic starting position of 550 Deg C again the starting temperature can be increased or decreased along with the air nozzle air flow.

Nozzle Air Flow

- The air flow will affect the actual temperature of the hot melt.

- The sum combination of the Nozzle Air Temperature and the Nozzle air flow = the ideal and most suitable required adhering conditions example. You can vary the conditions respectively by setting the nozzle temperature higher and the air flow lower or visa /versa.

- For 1 layer and 2 layer tapes we recommend a starting position of 0.6kgf/cm2.

- For 3 layer tapes we recommend a starting position of 1.2kgf/cm2.

Roller Temperature (if Applicable)

- Some machines are fitted with a heated upper roller again a heated will affect the temperature of the hot melt.

- It can be an increasing factor to have a roller fitted that can be adjusted in order to upgrade the adhesion at the start point of the seam taping process.

- We recommend a basic starting position below 80 Deg c for 2 layer tapes and below 130 Deg C for 3 layer tapes.

Upper Roller Pressure

- Sufficient pressure is required to give complete adhesion of seam sealing tapes.

- The amount of pressure will affect the outer appearance after adhesion such as puckering and ridging on the outer surface of the fabric surface.

- In a laboratory condition we can recommend a 5.0kgf/cm2 to give the optimum adhesiveness and waterproof ness.

- Factories and production hoever may opt to reduce the pressure to 2.0kgf/cm2 to give a better outer appearance after sealing.

- It must be noted that you must not reduce the toller pressure too much as it will lead to a water leak due to poor adhesion especially at the cross over points of the seam sealing tapes.

Machine Roller Speed

- The machine roller speed will affect the whole sealing process and adhering conditions. For example water pressure resistance, peel-off strength, outer fabric appearance such as puckering etc.

- Manufacturing productivity usually drives this setting but it is essential to discuss the productivity target before deciding any of the above machine settings.

- We would recommend a basic starting position for 1 and 2 layer tape 4-5m/min and 3 layer tapes at 3m/min.